TITANIUM - PIPES

Ratnam Alloys are well Known Exporters, Suppliers & Stockiest of high quality Titanium pipes and tubes.

Titanium Pipe Exporters | Titanium Pipe Suppliers | Titanium Pipe Stockiest | Titanium Pipe Mumbai | Titanium Pipe India

Titanium Tube Exporters | Titanium Tube Suppliers | Titanium Tube Stockiest | Titanium Tube Mumbai | Titanium Tube India

Titanium is the ninth most abundant element in the earth's crust and the fourth most commonly used structural metal. In nature, it occurs only as a mineral (ore) in combination with oxygen or iron (rutile, TiO2, or ilmenite, FeTiO3).

Titanium is a lightweight material whose density is approximately 60 percent of steel's and 50 percent of nickel and copper alloys'. It was recognized in the 1950s as a desirable material for aerospace applications—especially airframe and engine components. In the 1960s and 1970s, titanium was considered for use in vessels and heat exchangers in corrosive chemical process environments. Typical applications included marine, refinery, pulp and paper, chlorine and chlorate production, hydrometallurgy, and various other oxidizing and mildly reducing chemical services.

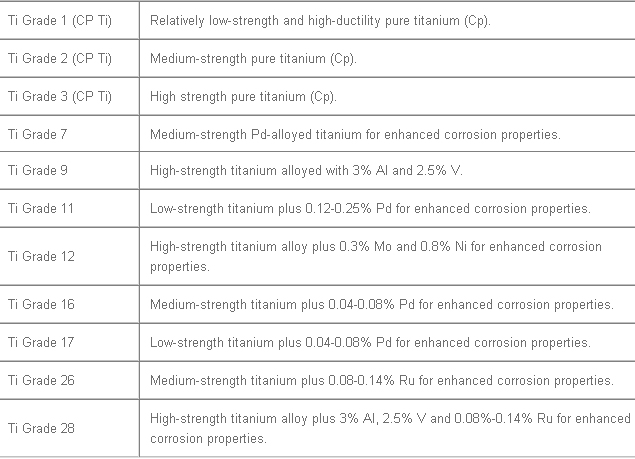

Properties of Titanium

Titanium is well-known for its unique combination of properties, which include low modulus of elasticity, stable and steadfast oxide film (which provides excellent corrosion and erosion resistance), and a high strength-to-density ratio.

Titanium's fabricability, weldability, and formability make possible its use in many shop and field operations. Although gas tungsten arc welding (GTAW) is the primary joining process, many other procedures are suitable. Titanium's weld characteristics are similar to those of stainless steels' or nickel alloys', with surface cleanliness and inert gas shielding being important. Fabricators often perform seal welding and butt welding operations in the shop and the field.

As for formability, titanium can be bent, cold-formed, and drawn readily. Furthermore, most industrial titanium alloys do not require stress relief annealing after cold forming.

Welded titanium tube and pipe can be tested with many of the same techniques used for steel tube and pipe. Eddy current, pneumatic, and ultrasonic testing all are applicable to titanium. Procedures for eddy current and ultrasonic testing can be used to meet or exceed American Society for Testing and Materials (ASTM) B-338 and to help ensure tube reliability.

Titanium Tubes

Seamless Tube

Seamless Tube

OD - 1/8" (3.18 mm) to 1-1/2" (38.1mm)

Wall - 0.016" (4 mm) to .065" (1.65 mm)

Welded Tube

OD - 1/2" (12.7 mm) to 2" (50.8 mm)

Wall - .028" (.71 mm) to .065" (1.65 mm)

Titanium Pipe

Seamless Pipe

1/8" NPS through 6" NPS

Sch 10S and Sch 40S x 20' RL max

Welded Pipe

3/4" NPS through 24" NPS Sch 10S and

Sch 40S x 20' RL max.